BrewVic setup an event where ~25 of us will brew using the exact same ingredients and compare how the resulting beer comes out.

For my version, I brewed on my BIABasket using my Cheapo Herms and my new pump. I crushed the grain at home on my JSP Maltmill set to around a ~0.030″ gap. This provided a finer crush than I had been getting at the homebrew shop.

I used a two stage water filter with an initial Doulton Sterasyl Ceramic OBE filter cartridge to knock out sediment followed by a KDF/GAC Filter Cartridge aimed at removing chlorine and chloramine.

I utilized BIABCalculator to determine the volume and temperature of strike water. It ended up recommending 6.97 gallons at 158*F. I touched up the temperature every 15 minutes by stirring and turning the propane burner on low.

I did an early touchup without taking notes. For all my later touchups I recorded the values:

| Time | Previous Temp | Liquid Temp | Grain Temp | Anova SP | Anova Temp |

| 30m | 152F @20m in | 149F | 151F | 162F | 158F |

| 45m | 152F | 148F | 149F | 162F | 156F |

| 60m | 151F | 148F | 149F | 167F | 156F |

My new 24″ Stainless Whisk worked superbly at mixing in the grains and at resuspending the mash while adding heat. Much nicer than the spoon I had been using.

My target volume of wort was 6.5 gallons. I collected 6 gallons with no squeezing, 6.25 gallons after light squeezing. I added 0.25 gallons of filtered water to bring it up to volume. It seems like my grain absorption gallong/lb is more like 0.1 (no squeeze) not my guesstimated 0.045.

At the start of boil I added 3 drops of fermcap to avoid excessive foaming.

Instead of my normal hop spider, I rinsed the BIABasket and used that to contain the hop additions. It was a mistake. The basked clogged with hop particulate and made draining the wort a real pain. Ultimately I poured the 1.5 gallons or so through the hop spider to filter it but let it flow out to the carboy. In future; I will stick to the hop spider from the get go.

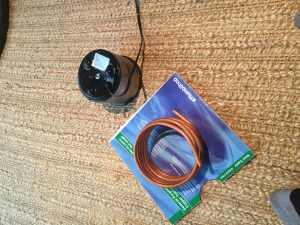

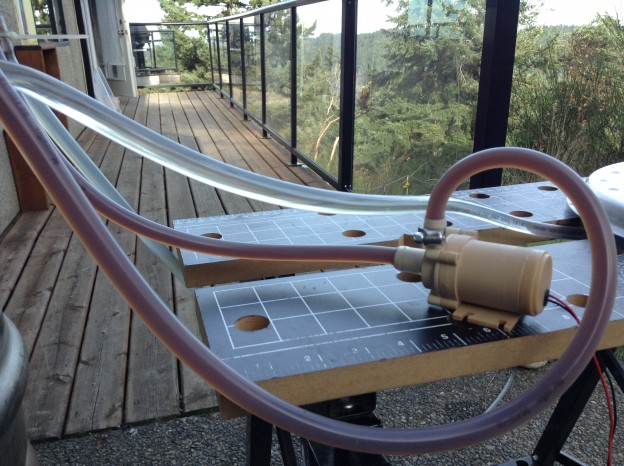

I used an immersion chiller and recirculated with my pump to speed it up. I start pumping with 10 minutes left in the boil to sanitize. I had to shut off the pump after ~20 minutes as the basket was clogged and filling. I chilled for ~15 more minutes to get it down to ~24*C.

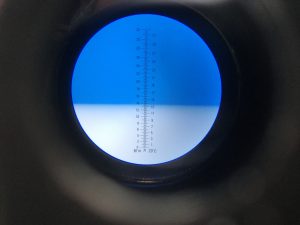

The recipe targeted 1.052 for OG, I measured 13.6Brix which converts to 1.054 in BeerSmith2.

The yeast was dry pitched. I added ~4ml of concentrated clarity ferm with the goal of reducing gluten. I hit it with 60 seconds of pure O2 using a stainless diffusing stone.

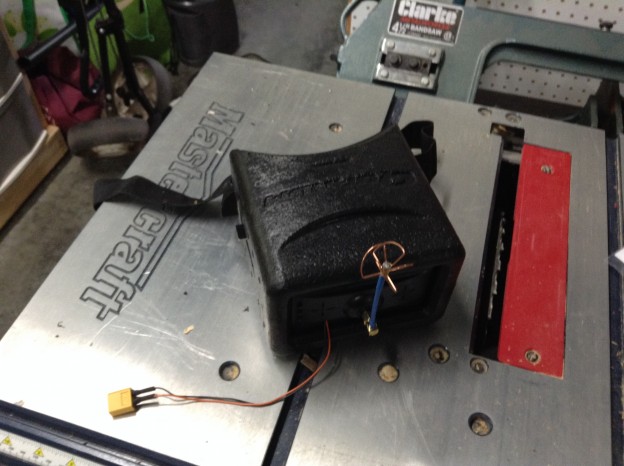

The beer is being fermented in my temperature chamber using a DIY Black Box Brew. It’s running the default profile 0 which is:

- 19C for 3 days

- ramps to 21C over half a day

- 21C for 3 days

- Cool to ~7C over ~2 days (it’s targeting 1C but my fridge won’t go that cold)

I plan to dry hop for 4 days once it’s chilled. I will toss the hops in loose and use a filter bag over my racking cane to avoid them when transferring to keg.

[beerxml recipe=https://geoffnicol.com/wp-content/uploads/2017/04/Fingerprint-Pale-Ale.xml]